VyCAP offers an innovative solution to measure and analyze the protein secretion by single cells for rapid antibody discovery. The followed by isolation of the cells that secreted the molecules of interest.

The innovative solution consists of a combination of our single cell microwell chip in connection with an antigen activated surface. The antibody produced by the single cells is “printed” by the microwells onto this activated surface and detected and analyzed by common methods like ELISA. The high quality images of the single cells inside the microwells in combination with our Puncher system provides an efficient workflow for monoclonal cell line generation.

Applications are :

- Screening of antibody producing cell lines and selection of the best producing cells for clonal expansion

- Monitoring the antibody producing cell lines on the quality and quantity of the produced antibodies

- Screening single B-cells for antibody discovery followed by the isolation and determination of the IgG sequences

- Screening for new therapeutic targets

- Drug efficacy measurements at the single cell level

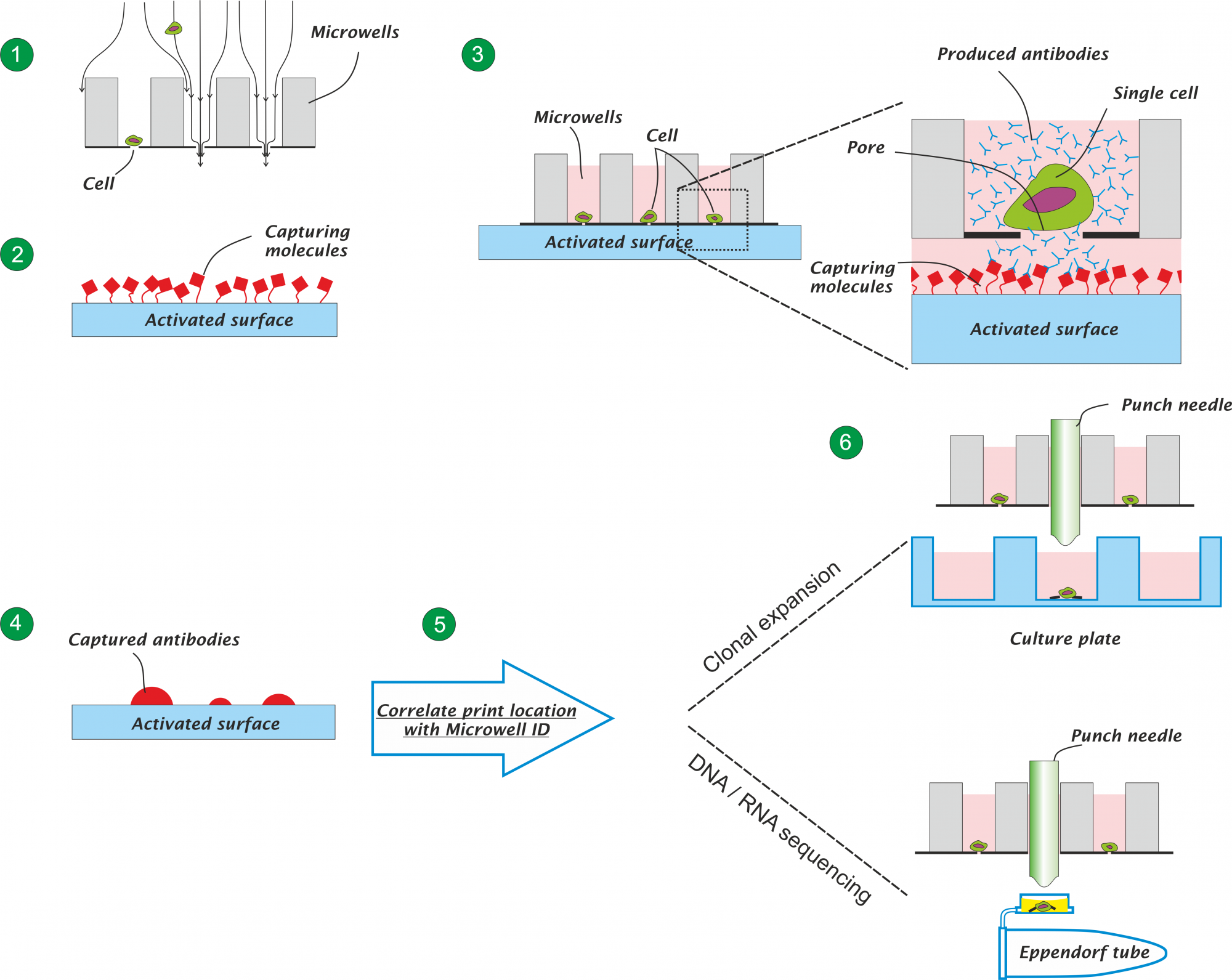

Workflow to select single cells based on their secretion profiles

A schematic picture of the workflow is presented in the figure below.

- Distribute single cells in the individual well of the microwell chip

- Activated the capturing surface with your capturing molecule of choice

- Connect the microwells to the activated surface

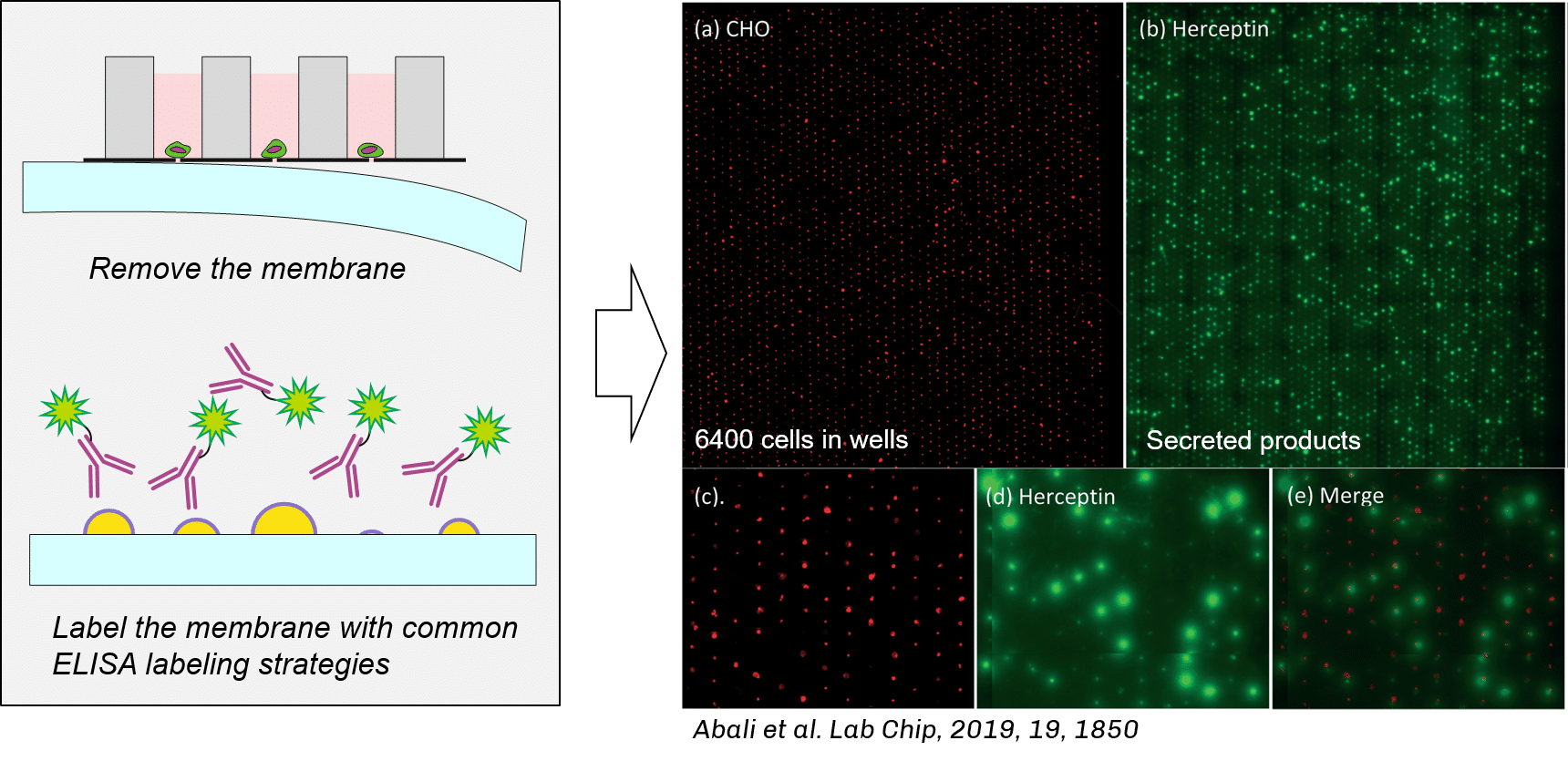

- After incubation, remove the membrane from the microwells and analyze the printed molecules

- Correlate the printed location with the microwells ID

- Isolate the cell of interest for clonal expansion or DNA / RNA sequencing

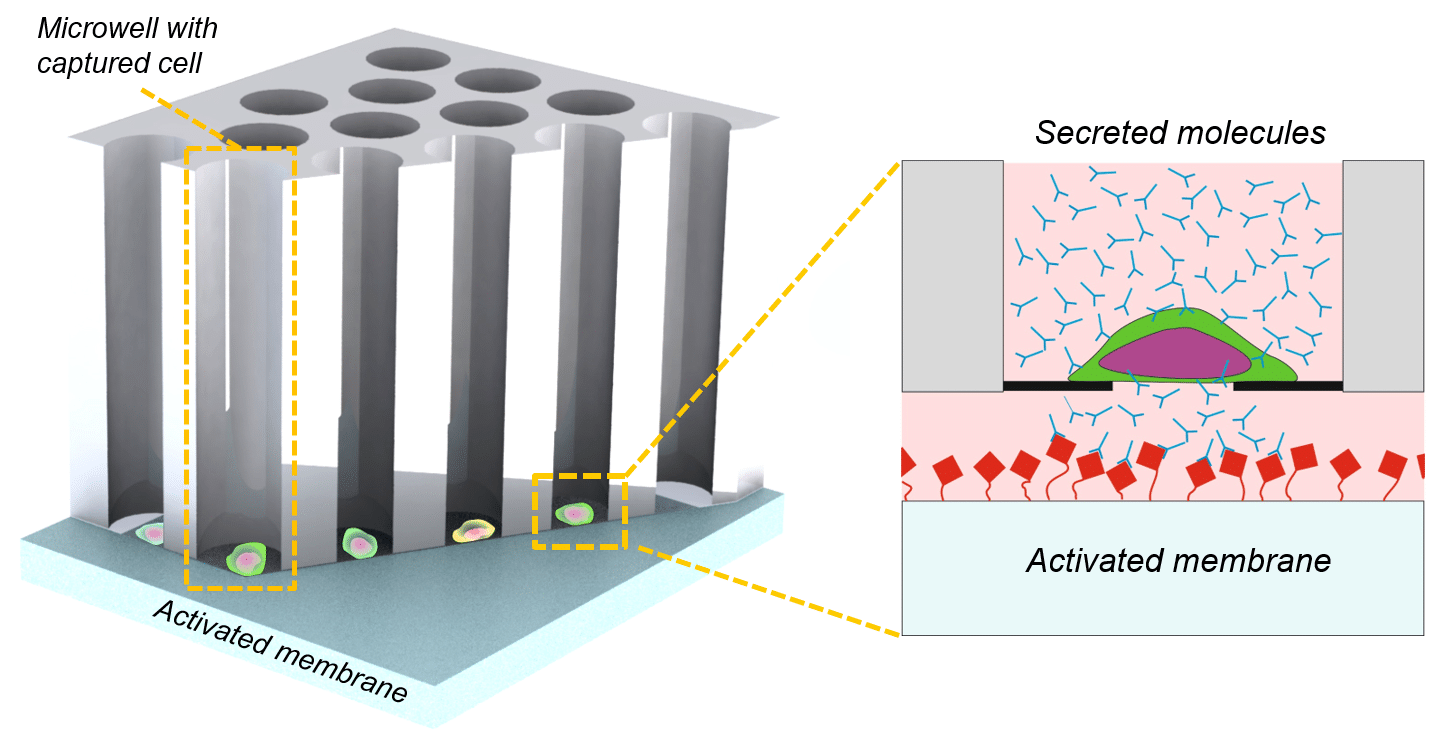

Printing antibodies on a surface

After the cells are distributed the microwells the activated surface is connected to the bottom of the microwells. The ensure a good connection between the bottom of the microwell and the activated surface, the microwell is mechanically clamped against the surface. The microwells, with the clamped activated surface against it, is placed in an incubator. The antibodies produced by the cells are printed by diffusion, through the pore present the bottom of the microwells, onto the activated surface. Depending on the production rate of the cells this combination is left in the incubator for 2 – 72 hrs.

Correlate the printed antibodies with the microwell

After incubation the microwell chip and membrane with the printed antibodies are separated from each other. The printed antibodies are made visible using an anti-IgG fluorescent label. Next the activated surface is scanned using one of the fluorescent channels of the Puncher system. The printed antibodies appear as bright green fluorescent spots on the activated surface. The image below presents the cells in the microwells in red. The produced antibodies are fluorescently labelled and appear as the green larger dots (Lab Chip, 2019, 19, 1850).

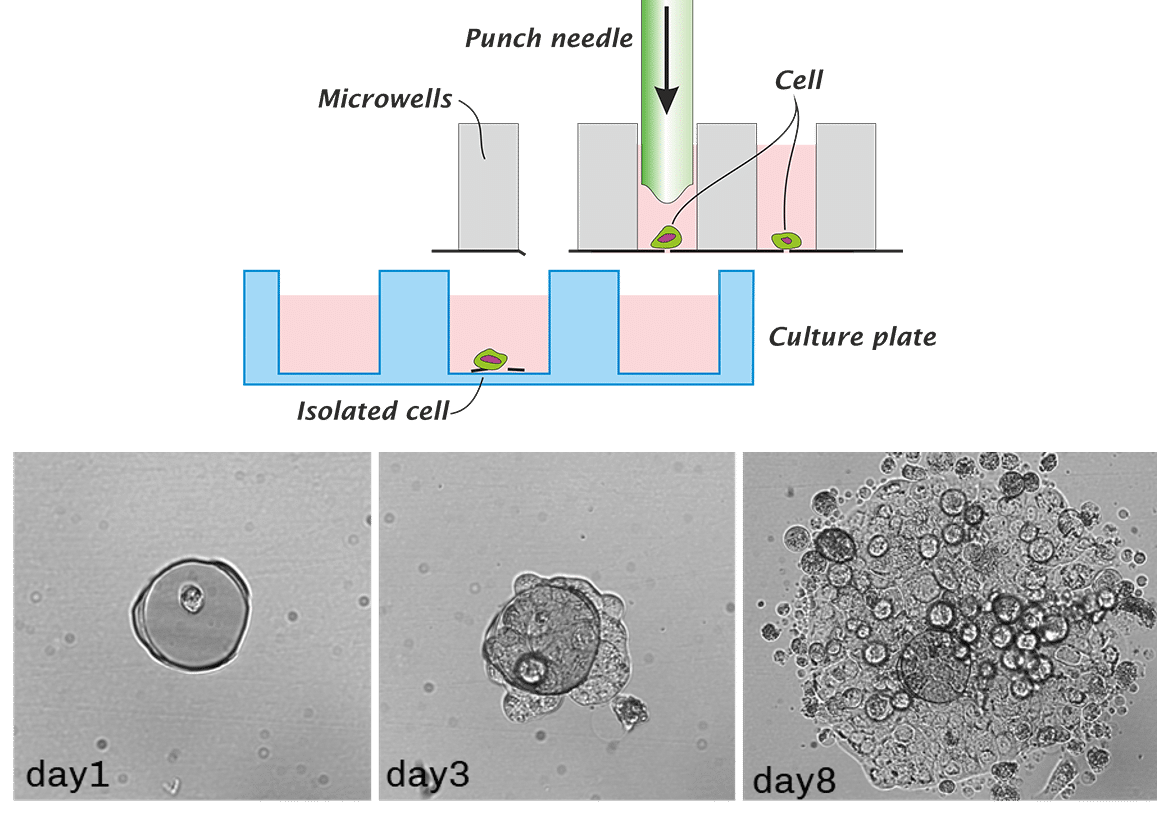

Isolate high producer cells for monoclonal expansion

By correlating the location the printed spots with the location of the microwells the cells that produced the highest amount of antibodies can be relocated. Next these cells are isolated and transferred to a culture plate for clonal expansion.